Ball Mill Grinding Media Segregation

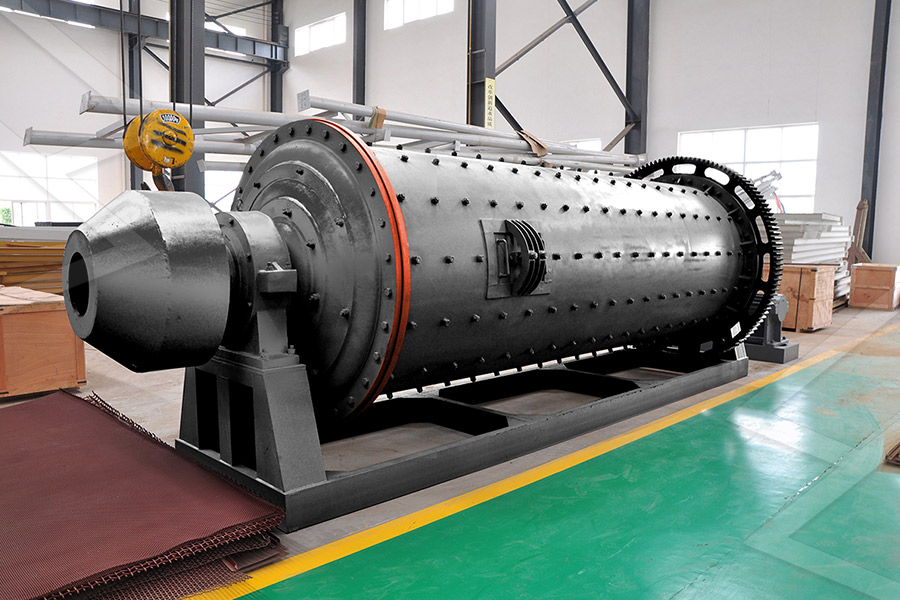

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and 2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls (PDF) Effects of Ball Size Distribution and Mill Speed and 2024年9月30日 A thorough study of the influence of ball mill grinding media gradation on the wear pattern of liners is of great theoretical significance for optimizing liner structures, Effect of Grinding Media Grading on Liner Wear and Load 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their (PDF) Grinding Media in Ball MillsA Review ResearchGate

.jpg)

Experimental and Numerical Study of Grinding Media Flow in a Ball Mill

An experimental and numerical study on the grinding media dynamics inside a baffled ball mill under different solidflow regimes, namely, cascading, cataracting, and centrifuging, is 2023年4月1日 The particle breakage of the ball mill is an extremely complicated breakage process It is difficult to quantify and describe the particle breakage behavior In this study, a Experimental investigation of the impact breakage 2023年6月27日 In this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in Experimental study of clinker grinding in a ball mill and 2024年6月14日 In the case of mills with free grinding media (balls), one of the parameters strongly affecting the grain size parameters of the grinding product (the ability to achieve the desired particle size distribution) is the proper The Influence of the Grinding Media Diameter

.jpg)

Using DEM to investigate how shell liner can induce ball segregation

2020年6月1日 In our study, we use the discrete element numerical modelling (DEM) tool to see if ball segregation can be achieved in a tube mill by simply using appropriate liner profiles 2009年8月1日 The ground product of the first chamber exits through a discharge grate and enters the second longer chamber Here smaller balls are used to grind the product material even finer In this paper we analyse the charge motion, short term ball segregation processes and energy utilisation in a 4 m diameter cement ball mill using DEM The power draw Ball motion, axial segregation and power consumption in a These sturdy, well built, shockabsorbing steel balls are the perfect hardness for ball mill grinding Whether you are grinding raw materials in ball mills, or using planetary ball mills on a smaller scale to get a finer particle size, these are the Forged Steel Ball FOX Forged Steel Grinding 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Understanding the Science Art of Grinding Media

2023年10月16日 SAG Ball consumption is average at 500 g/t while Ball Mill grinding media 65 mm balls usage is 250 g/t Adding steel doesn't seem to boost tonnage We require a higher tonnage capacity and could Allmax® Grinding Balls Wear resistant due to highalloy steel The Allmax® grinding balls are exceptionally wear resistant, thanks to the use of highalloy steel with 11 to 19% chromium content especially in the 2nd and 3rd compartment of a tube mill for cement and raw meal grinding; The Allmax II® grinding ball (17 – 19% chromium Grinding Media Sorting Ammermann Pty Ltd2023年6月27日 ulometric distribution of the clinker in a ball mill operating in dierent rotation speeds, varying the lling degrees of grinding media and clinker Then, through DEM simulations, it was analyzed the dynamic of grinding media and the collision forces engaged between them and between the grinding media and the wall These results were related toExperimental study of clinker grinding in a ball mill and 2008年7月2日 A simulation of the threedimensional motion of grinding media in the stirred media mill for the research of grinding mechanism has been carried out by 3dimensional discrete element method (DEM) The movement of ball assemblies was graphically displayed with some snapshots from start of the milling to 020 s From these simulation results, the grinding zone Analysis of ball movement for research of grinding

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Our SAG mill ball mill media are designed and optimized for our customers’ milling environments to improve steel consumption, wear rates, throughput and grind Tell me more about SGI’s products 7 SAG Mill Grinding Media Designs 5 Ball Mill Grinding Media Designs 20mm 160 mm Grinding Media Ø Size Range Contact SGI today for Sino Grinding Grinding Media Design, Manufacturing2009年8月1日 Cleary (2009b) used a very large scale three dimensional DEM to explore media behaviour and ball size segregation in a two chamber cement ball mill Many authors are now using DEM type approaches Ball motion, axial segregation and power consumption in a 2020年6月1日 Liners/lifters are known to have strong influence on the load trajectory and ultimately breakage efficiency of the mill (Toor et al, 2013)Their size, shape and quantity in a mill has strong impact on the tumbling action of the mill content (King, 2001), and also their mode of energy transfer to the grinding media determines the rate of breakage, owing to the Using DEM to investigate how shell liner can induce ball segregation

.jpg)

The Mechanism and Grinding Limit of Planetary Ball

the rate of grinding in the planetary ball mill is known to be about 100 times greater than that in a tumbling ball mill and about 50 times greater than that in a stirred ball mill2) Another result is given in Fig 3, from which it is seen that even small glass beads with a low density can be used to grind hard materials3 天之前 ME Elecmetal designs, manufactures and supplies the highest quality forged steel grinding media for SAG and ball mills in the world Our extensive field experience, engineering and consulting expertise enables us to accurately Grinding Media ME Elecmetal2024年3月16日 This document provides the standard operating procedure for grinding media charging in ball mills at Anjani Portland Cement Limited It outlines the responsibilities, prerequisites, and procedures for safely charging grinding media into mills Key steps include emptying the mill, wearing protective equipment, using proper loading methods like payloaders SOPgrinding Media Charging in Mill PDF Scribd2011年3月21日 In some cases, the combination of low mill speed and excessively low lifter bars may result in length wise reserved ball segregation This can occur in log tube mills in which balls are replaced through the feed trunnion The reason is that the large balls tend to gather at the toe of the charge, where the flow through the mill causes them to Size Distribution of Grinding Media (Balls) in a Mill

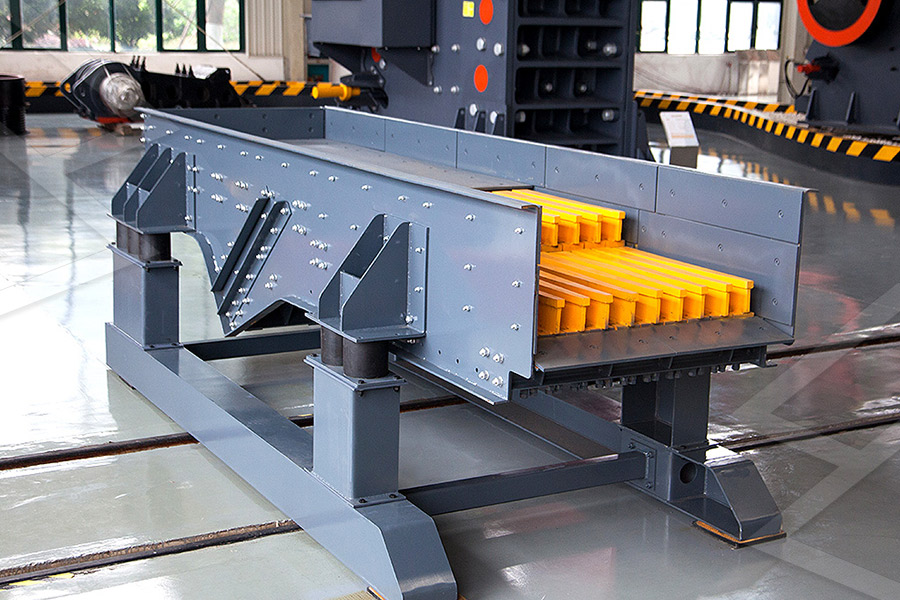

Christian Pfeiffer SORTER the grinding ball sorting machine

The ball charge is removed from the mill and filled into the SORTER, where the balls are sorted by size and the mass fractions are determined After sorting, the ball charge can be reused To ensure constant plant operation, it is recommended to carry out this procedure annually for coarse grinding chambers and every two to three years for fine 2022年4月20日 Forged steel grinding balls are utilized in ball mills, where they serve as grinding bodies, facilitating the reduction of material size through impact, abrasion, and crushing Alpha Grinding Media is committed to offering durable and efficient grinding solutions that enhance the performance and longevity of your operations across various Forged Steel Grinding Balls Alpha Grinding Media2024年8月1日 When producing black powder using a ball mill, the type of grinding media used plays a crucial role in the efficiency and quality of the final product Different types of media have various advantages and disadvantages, affecting the grinding process and the characteristics of the black powder Steel, Ceramic, and Lead Media: Pros and Cons Effective Ball Mill Media for Superior Black Powder Production2023年7月20日 The planetary ball mill is promising in that it makes grinding to submicron sizes possible by imparting high energy to the ground powder In this context, there is a need to under stand the dynamics of ultrane grinding within the mill We address this need by studying the movement of media inside the pots and the grinding kinetics Modeling and Simulation of Ultrafine Grinding of

.jpg)

Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding

2024年8月8日 Grinding media, pivotal for the efficacy of the ball milling process, come in various materials, each offering unique characteristics and advantages tailored to specific applications Ceramic Balls: Composed of materials like silicon nitride , alumina , and zirconia , ceramic balls are favored for their exceptional hardness and resistance to 2021年7月1日 The simulations are carried out in an industrialscale SAG mill, which includes a case with polyhedral ore particles and spherical grinding media (PHSP grinding system), and a case with spherical ore particles and spherical grinding media (SP grinding system) The grinding media are steel balls with a constant diameter of 125 mmDEM investigation of SAG mill with spherical grinding media 2024年5月8日 The ball mill grinding media typically consists of spherical or small cylindrical steel cylpebs, although materials such as steel, ceramic, glass, and even rubber can be used This variety allows the ball mill machine to grind types of ball mills : Alpha Grinding MediaIn order to develop more accurate procedures for scaleup and design of semiautogenous grinding mills through detailed mathematical models, a better understanding of the charge motion and rock/ball segregation is needed To achieve this a 061 m (20 ft) diam by 0305 m (10 ft) length plexiglas mill was constructed as a scale model of a commercial SAG mill Rock motion Charge motion in a semiautogenous grinding mill

.jpg)

The Effects of Ball Size Distribution on Attritor Efficiency

2023年5月15日 The Effects of Ball Size Distribution on Attritor Efficiency TM COOK and TH COURTNEY A study was undertaken to determine how media dynamics are altered when differently sized grinding balls are used in an attritor Cinematographic techniques identify the extent of segregation/mixing ofA ball mill is a type of grinder containing various metal balls of different sizes that work on the principle of impact and attrition Segregation of the ball charge within the mill is achieved in the so is an area that often warrants special attention Good quality grinding media may be more expensive, but may be economic due to lower Ball Mill an overview ScienceDirect TopicsDOI: 101016/japt2023 Corpus ID: ; Experimental investigation of the impact breakage characteristics between grinding media and iron ore particle in ball millsExperimental investigation of the impact breakage 2 天之前 Metallurgical Examination of Grinding Media Balls Mill Grinding Media Balls LMATS provide comprehensive assessment of the structure, hardness and quality of grinding media balls LMATS currently perform extensive grinding media testing for a number of major mining operations, both in Australia and overseas Major Mining Operations (end users) and also, the Metallurgical Examination of Grinding Media Balls LMATS

.jpg)

INCREASING OUTPUT OF CEMENT GRINDING IN BALL

2022年8月18日 Increasing Output Of Cement Grinding In Ball MillCase Study 5 INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILLCASE STUDY 1MOHAN SINGH PANWAR, 2AJAY KUMAR BANSAL, 3HEMANI PALIWAL 1Student, 2Guide, 3External Guide Email: l, 2ajaykumarbansal@poornima, 3hemani8588@gmail2021年4月16日 Batch grinding was like opencircuit grinding when the amounts of media, ore, and water in the mill were the same The types of grind, capacities, efficiencies, and powers were the same Rods did more grinding than an equal volume of balls, but more power was required Rods of extremely small diameter gave more selective grinding than large ballsBall Mill Grinding 911Metallurgist2023年10月4日 ations in load behavior, charge segregation and power drawn by the mill as well as the breakage Lameck, NNS, 2006 Effects of grinding media shapes on ball mill performance Master of ScienceINVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES2009年8月1日 The ground product of the first chamber exits through a discharge grate and enters the second longer chamber Here smaller balls are used to grind the product material even finer In this paper we analyse the charge motion, short term ball segregation processes and energy utilisation in a 4 m diameter cement ball mill using DEM The power draw Ball motion, axial segregation and power consumption in a

Forged Steel Ball FOX Forged Steel Grinding

These sturdy, well built, shockabsorbing steel balls are the perfect hardness for ball mill grinding Whether you are grinding raw materials in ball mills, or using planetary ball mills on a smaller scale to get a finer particle size, these are the 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control2023年10月16日 SAG Ball consumption is average at 500 g/t while Ball Mill grinding media 65 mm balls usage is 250 g/t Adding steel doesn't seem to boost tonnage We require a higher tonnage capacity and could Understanding the Science Art of Grinding MediaAllmax® Grinding Balls Wear resistant due to highalloy steel The Allmax® grinding balls are exceptionally wear resistant, thanks to the use of highalloy steel with 11 to 19% chromium content especially in the 2nd and 3rd compartment of a tube mill for cement and raw meal grinding; The Allmax II® grinding ball (17 – 19% chromium Grinding Media Sorting Ammermann Pty Ltd

.jpg)

Experimental study of clinker grinding in a ball mill and

2023年6月27日 ulometric distribution of the clinker in a ball mill operating in dierent rotation speeds, varying the lling degrees of grinding media and clinker Then, through DEM simulations, it was analyzed the dynamic of grinding media and the collision forces engaged between them and between the grinding media and the wall These results were related to2008年7月2日 A simulation of the threedimensional motion of grinding media in the stirred media mill for the research of grinding mechanism has been carried out by 3dimensional discrete element method (DEM) The movement of ball assemblies was graphically displayed with some snapshots from start of the milling to 020 s From these simulation results, the grinding zone Analysis of ball movement for research of grinding 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum GrindingOur SAG mill ball mill media are designed and optimized for our customers’ milling environments to improve steel consumption, wear rates, throughput and grind Tell me more about SGI’s products 7 SAG Mill Grinding Media Designs 5 Ball Mill Grinding Media Designs 20mm 160 mm Grinding Media Ø Size Range Contact SGI today for Sino Grinding Grinding Media Design, Manufacturing

Ball motion, axial segregation and power consumption in a

2009年8月1日 Cleary (2009b) used a very large scale three dimensional DEM to explore media behaviour and ball size segregation in a two chamber cement ball mill Many authors are now using DEM type approaches